Brand: TSM

Material: Titanium and Titanium Alloy

Major Diameter: 3.5mm~6.3mm or Customized

Length: 12.7 mm~300 mm or Customized

Standards: ASTM, DIN, JIS, BS, GB/T

EN10204 3.1/3.2, Third Party Inspection Report, etc

Delivery time: 10-25 days

Payment terms: T/T, L/C, Paypal, West Union or as required

Titanium self tapping screw is a type of fastener designed to drill its hole as it is driven into material, eliminating the need for a pre-drilled pilot hole. They are used to connect thin metal sheets. When connecting to the connecting piece for the threaded hole, then tapping screws into the threaded hole of the connecting piece. Titanium screws are favored for their high strength-to-weight ratio, corrosion resistance, and biocompatibility, making them ideal for demanding applications.

Types of Self Drilling Screw

1. Pan Head, Flat Head, Hex Head (various drive types).

2. Fine or Coarse Threads (depending on material).

3. Point Types (sharp gimlet point for metal, blunt for plastics).

The surface treatment

Ti Blue screws,Ti Purple screws,Ti Golden screws

Micro Arc Oxide supported

Thermal Heated Treatment

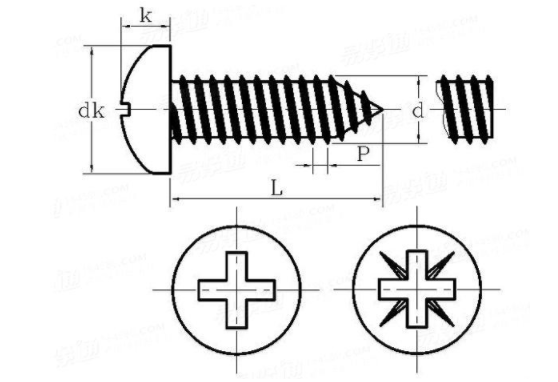

D | Pitch | DK(max) | DK(min) | K(max) | K(min) |

ST2.2 | 0.8 | 4.2 | 3.9 | 1.8 | 1.55 |

ST2.9 | 1.1 | 5.6 | 5.3 | 2.2 | 1.95 |

ST3.5 | 1.3 | 6.9 | 6.54 | 2.6 | 2.35 |

ST3.9 | 1.3 | 7.5 | 7.14 | 2.8 | 2.55 |

ST4.2 | 1.4 | 8.2 | 7.84 | 3.05 | 2.75 |

ST4.8 | 1.6 | 9.5 | 9.14 | 3.55 | 3.25 |

ST5.5 | 1.8 | 10.8 | 10.37 | 3.95 | 3.65 |

ST6.3 | 1.8 | 12.5 | 12.07 | 4.55 | 4.25 |

Key Features of Titanium Self tapping Screw

Made from titanium alloys (e.g., Grade 2, Grade 5 [Ti-6Al-4V]).

🔹Lightweight yet stronger than steel (by weight).

🔹Corrosion-resistant, especially in saltwater and chemical environments.

🔹Biocompatible (used in medical implants).

🔹Self-Tapping Design:

Sharp, cutting threads that create mating threads in the material.

Available in thread-forming (for plastics) or thread-cutting (for metal) styles.

Advantages Over Steel Screws

Lighter weight without sacrificing strength.

Superior corrosion resistance (does not rust like stainless steel).

Non-magnetic (useful in electronics and MRI environments).

High-temperature resistance.

Disadvantages

More expensive than steel or aluminum screws.

Softer than steel, so may gall (cold-weld) if not properly installed.

Requires proper installation technique (e.g., lubrication to prevent seizing).

Applications of Titanium Self tapping Screw

✔Aerospace & Marine (due to corrosion resistance).

✔Medical implants & devices (biocompatibility).

✔Automotive & Racing (lightweight strength).

✔Electronics (non-magnetic properties).

✔Industrial & Construction (high-performance fastening).

Why Choose TSM titanium Self Tapering Screws?

Besides > M3 screws,M1,M1.6,M2,M2.5 micro bolts supported

Short lead time around 1week

Each bolt inspected and polished

Quanlity Certificate will be offered free.

Contact us

For more details on Titanium Self tapping Screw or to obtain a quote, please contact TSM TECHNOLOGY CO., LTD at: info@tsmfasteners.com. We look forward to working with you to provide high-quality fastener solutions for your project.

Keywords: Self Drilling Screw,Titanium Self Drilling Screw,Titanium Self tapping Screw

TSM Fasteners Equipment and Packing

FAQ

Q.If we travel to China to checking your facility, are you welcome?

A.Of course, why not?we will provide the whole accompany from you landing in China.

Q: Can I be you dealer in my country?

A.Yes,sure but we already have some dealers in 23countries,we have to check if that area is empty,if so,we can make deal.please email me about your requirement.

Q: How long is your warranty time?

A.Our warranty is for one year free,but life-long service will be offered.