Material: Copper

Surface Treatment: Bare copper, tin plating, nickel plating, silver plating

Size :M2.5-M32 or Customized

Length: 1mm-1990 mm or customized

Standards: ASTM, DIN, JIS,BS, GB/T

EN10204 3.1/3.2, Third Party Inspection Report, etc

Delivery time: 10-25 days

Payment terms: T/T, L/C, Paypal, West Union or as required

As a world-renowned fastener manufacturer and supplier, TSM TECHNOLOGY CO., LTD. is committed to providing high-quality copper hexagonal nuts to meet the needs of various industries for high-performance fasteners.

What is a Copper Hex Nuts?

Copper hex nuts are made of copper or copper alloys, mainly used to support and connect bolts or screws. They are known for their excellent electrical conductivity, thermal conductivity and corrosion resistance. These nuts are widely used in electrical systems, marine hardware, chemical processing equipment, etc.

Copper Hex NutsTechnical specifications:

Material grade | C11000 (electrolytic copper) | C12200 (phosphorus deoxidized copper) | C10200 (oxygen-free copper) | customized |

Thread Type | Metric thread (M2-M48) | Imperial thread (1/8"-2") | coarse and fine threads available | customized |

Surface Treatment | Bare copper | nickel plating | tin plating | silver plating |

Features of Copper Hex Nuts

Copper hex nuts are widely used in various industrial applications due to their excellent mechanical and chemical properties. Here are the key features:

✅Corrosion Resistance:

Excellent resistance to corrosion, especially in marine, chemical, and humid environments.

Ideal for outdoor and high-moisture applications.

✅High Electrical Conductivity: Copper is one of the best conductors of electricity, making these nuts perfect for electrical and grounding applications.

✅Thermal Conductivity: High heat resistance and excellent thermal conductivity, useful in high-temperature applications.

✅Malleability & Ductility: Easy to machine and shape, allowing for precise manufacturing and customization.

✅Non-Magnetic Properties: Copper hex nuts are non-magnetic, making them suitable for sensitive electronic and scientific applications.

✅Aesthetic Appeal: Natural reddish-brown color that can develop an attractive patina over time, often used in architectural and decorative applications.

✅Anti-Galling & Anti-Seizing: Less prone to seizing or galling compared to steel or stainless steel fasteners, improving durability.

✅Chemical Compatibility: Resistant to various acids and chemicals, making them ideal for chemical processing industries.

Common Applications

✔ Electrical & grounding systems

✔ Plumbing & waterworks

✔ Marine & shipbuilding

✔ Aerospace & automotive industries

✔ Decorative & architectural projects

Why choose TSM?

Diverse materials: H62 brass (cost-effective), C36000 lead brass (easy to cut), TU1 oxygen-free copper (ultra-high conductivity), aluminum bronze (high temperature resistance).

Precision machining: CNC lathe + thread rolling process, precision reaches DIN 934 6g level, suitable for global standard threads (M2-M64, UNC/UNF).

Surface strengthening: optional nickel plating (wear resistance), tin plating (anti-oxidation), passivation (anti-salt spray).

TSM factory and Processing equipment

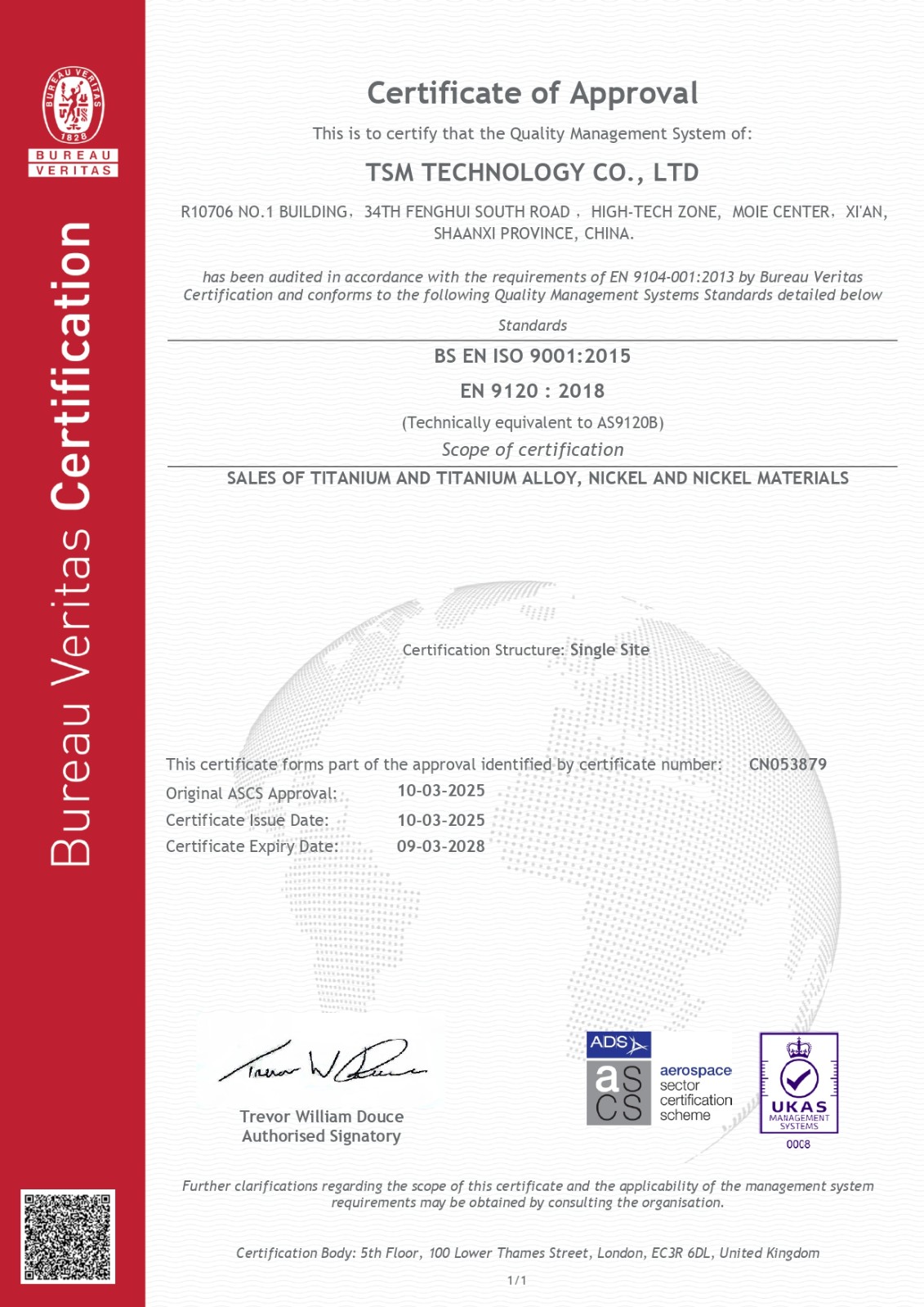

Certificate