Brand: TSM

Material: Nickel

Size :M3.5x40mm/50mm/75mm or Customized

Application: Mechanical manufacturing, Construction engineering, Automobile industry, Electronics and electrical appliances

Norm : BG NFS38/10BN

Delivery time: 10-25 days

Payment terms: T/T, L/C, Paypal, West Union or as required

TSM TECHNOLOGY CO., LTD. is a high-end fastener manufacturer certified by AS9100D, focusing on the research and development of black nickel screws, aerospace fasteners and special alloy parts. Our technical team has more than 20 years of industry experience and serves more than 50 companies worldwide. The factory is equipped with a full-process digital management system to ensure 100% traceability from raw materials to finished products.

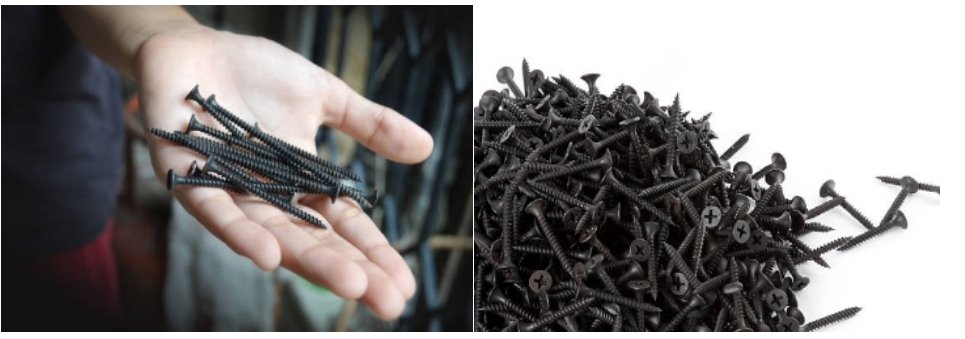

Product Introduction

Black nickel screws are fasteners made of high-quality black nickel plating technology. They have excellent corrosion resistance, oxidation resistance and excellent mechanical properties. With their unique black appearance and excellent protective function, this type of screw not only has unique advantages in aesthetics, but is also widely used in high-end fields such as aerospace, automobiles, electronics, furniture, decoration, etc., providing safe and durable connections for various equipment and structures.

Types of Black Nickel Screws

To adapt to different application scenarios, we provide a variety of types of black nickel socket screws, mainly including:

✔Hexagon head screws

✔Hexagon socket screws

✔Countersunk head screws

✔Cross slot/slot screws

✔Customized screws: Customize non-standard sizes, special head shapes or special coating effects according to your needs.

Alloy Type and Material Grade

Inconel® | 600/601/625/718 |

Hastelloy® | C276/C22/B3 |

Monel® | 400/K500 |

Incoloy® | 800/825 |

Nickel | 200/201 |

Main Features

Black nickel socket screws are precision screws that form a dense black nickel coating on the surface of nickel alloy through an electroplating process. The characteristics include:

1.Multi-layer electroplating process: bottom nickel (≥5μm) + black nickel layer (3–8μm), enhanced corrosion resistance (salt spray test ≥500 hours).

2.Matte black aesthetics: uniform black surface (color difference ΔE≤1.5), no fingerprint residue, suitable for high-end display equipment.

3.Environmentally friendly and non-toxic: Complies with RoHS/REACH regulations, with no hexavalent chromium or cadmium release risk.

4.Functional advantages: stable conductivity (resistivity ≤ 1.5 μΩ·cm), anti-electromagnetic interference (EMI).

Specifications Parameters

TSM Black Nickel Screws products cover a variety of specifications to meet the diverse needs of different customers and industries.

🔹Material: High-quality metal substrate treated with advanced black nickel electroplating

🔹Size range: Available in a range of sizes from micro to large (e.g., diameters from M1.5–M64, lengths customizable)

🔹Thread standards: Metric, imperial, self-tapping threads to ensure versatility and high precision

🔹Surface treatment: Uniform black nickel coating to enhance corrosion resistance, wear resistance and decorative effects

🔹Tolerance control: Product tolerances are strictly controlled by international standards to ensure high-precision assembly requirements

Application areas

Automotive industry: interior parts, in-car entertainment systems, electric sports car battery packs.

Aerospace: cabin interior panels, avionics equipment brackets.

Medical equipment: surgical instruments, MRI equipment housings.

High-end electronics: Smartphones, laptops, smart watches

Services we can provide

Customizable sizes: We offer a variety of sizes from M1.5 to M64 and provide customization options to meet specific project requirements.

Product certification: Provide complete material certification (3.1/3.2) and test reports to ensure traceability and compliance with industry standards.

Small batch trial production: MOQ 100 pieces, support sample orders without mold fees

Global logistics services: Provide reliable international logistics and transportation services, covering major markets around the world.

TSM Processing Capabilities

Precision cold heading: ±0.01mm tolerance, M1.5 ultra-fine screws mass production.

Electroplating process: fully automatic roller plating line, coating thickness uniformity ≥95%.

Heat treatment: vacuum quenching + low-temperature tempering to eliminate the risk of hydrogen embrittlement.

Surface treatment: black nickel, black zinc, PVD coating optional.

Contact us

For more details on black nickel screws or to obtain a quote, please contact TSM TECHNOLOGY CO., LTD at: info@tsmfasteners.com. We look forward to working with you to provide high-quality fastener solutions for your project.

Keywords: black nickel screws,black nickel long socket screws,black nickel socket screws 40mm,black nickel socket screws 75mm,black nickel socket screws,black nickel socket screws 50mm

TSM factory and Processing equipment

Certificate