Brand: TSM

Material: Nickel 200

Specifications: UNS N02200, EN 2.4060, EN 2.40666

Size:M1.2-M120 or Customized

Length: 1mm-1990 mm or customized

Application: Mechanical manufacturing, Construction engineering, Automobile industry, Electronics and electrical appliances

Standards: ASTM, DIN, JIS, BS, GB/T

Delivery time: 10-25 days

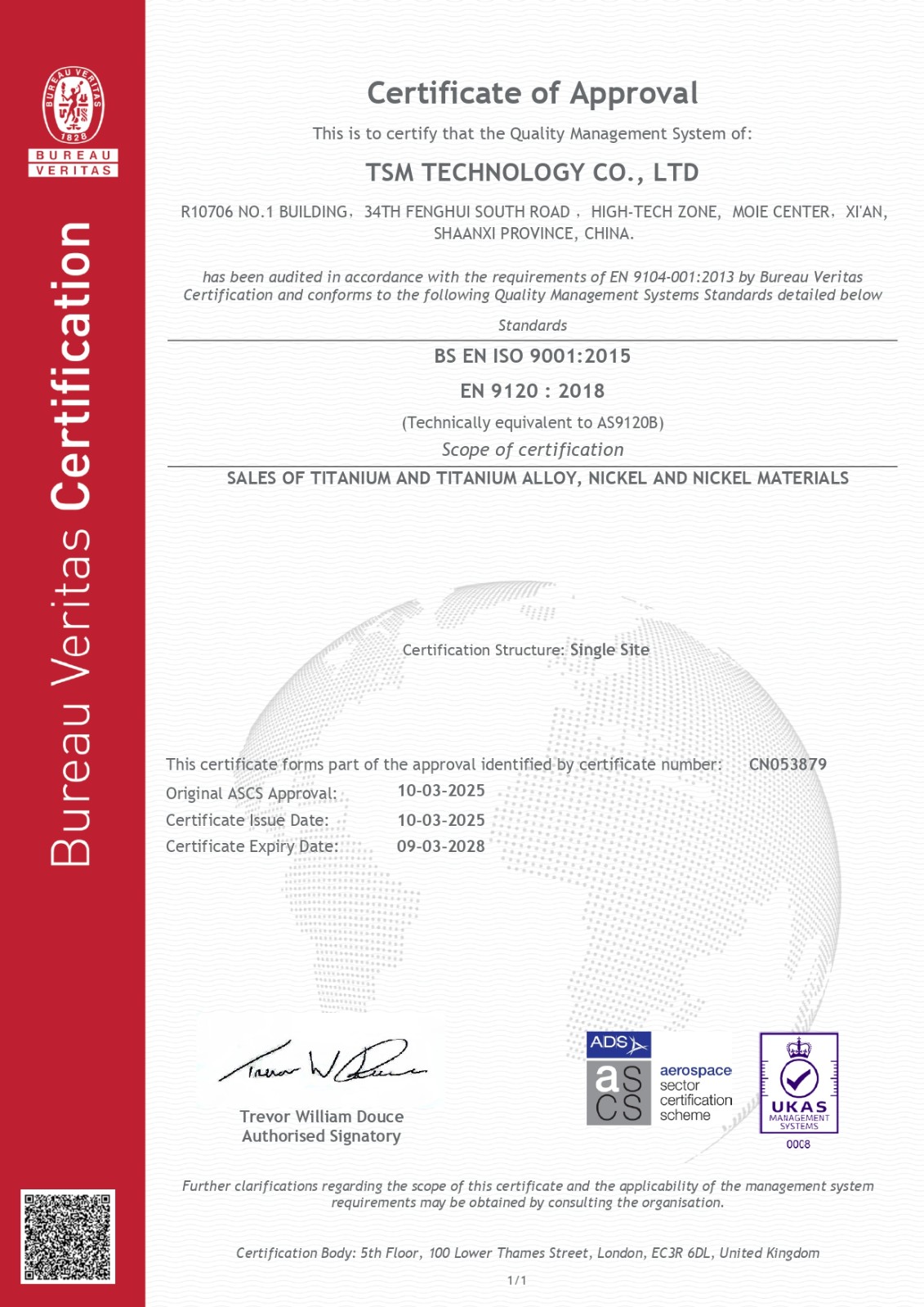

TSM TECHNOLOGY CO., LTD is a world-renowned manufacturer and supplier of high-quality Nickel 200 fasteners. We are AS9120 certified, ensuring that our products meet the quality requirements of aerospace and other high-tech industries. With years of industry experience, TSM is committed to providing real and reliable fastener solutions to customers worldwide.

What are Nickel 200 Fasteners?

Nickel 200 Fasteners are fasteners made of commercially pure nickel alloy (Nickel 200). The material is mainly composed of 99.6% nickel and has extremely high corrosion resistance, excellent oxidation resistance and good mechanical strength, suitable for a variety of harsh environments. Through precision processing and surface treatment, Nickel 200 Fasteners can achieve efficient and durable connection solutions in fields such as chemical, marine and aviation.

Specification

Our Nickel 200 Fasteners products have a variety of specifications and parameters to meet the application needs of different industries, mainly including:

Size | M1.2-M120 or Customized |

Length: | 1mm-1990 mm or customized |

Threads: | METRIC, BSW, BSF, UNC, UNF or as required |

Material: | Commercially pure nickel alloy (Nickel 200), nickel content up to 99.6% |

Surface treatment: | Available with natural, polished or coated surface treatment to enhance performance in specific environments. |

Standard: | DIN: DIN 931, DIN 933, DIN 934, DIN 970 UTS – Unified Thread Standard : UNC, UNF, UNEF, UNS, NPT, NPTF ISO – International Organization for Standardization : ISO 4032, ISO 4033, JIS standards |

Packing: | canton, pallet, Small Boxs / carton / pallet, or customer request |

Nickel 200 Fasteners Type

To adapt to different application scenarios, we provide a variety of types of Nickel 200 Fasteners, mainly including but not limited to:

Nickel 200 Nuts

Nickel 200 Washers

Nickel 200 Screws

Nickel 200 Socket Cap Screws

Nickel 200 Studs

Nickel 200 U-bolts

Nickel 200 Hex Bolts

Nickel 200 Hex Cap Screws

Incoloy 200(N02200/2.4060/Nickel200) | |||||||||||

Chemical Composition

| % | Ni | Fe | C | Mn | S | Si | Cu | |||

min | Remaining amount | ||||||||||

max | Remaining amount | 0.4 | 0.152 | 0.35 | 0.01 | 0.35 | 0.25 | ||||

Physical Characteristics | Density | 8.89g/cm³ | |||||||||

Melting point | 1440℃ | ||||||||||

Minimum mechanical properties of alloys at room temperature | Alloy state | tensile strength Rm N/mm² | Yield Strength RP 0.2 N/mm² | Elongation A5% | |||||||

Applications

Due to their excellent corrosion resistance and high mechanical strength, Nickel 200 Fasteners are widely used in a variety of fields:

✔Aerospace

✔Chemical Industry

✔Offshore Engineering

✔Food and Pharmaceuticals

✔Electronic and Electrical

Services We Provide

TSM TECHNOLOGY CO., LTD We are committed to providing customers with a comprehensive service experience and ensuring that every customer can get a tailor-made solution:

🔹Product customization:

Provide personalized customization services such as size, shape and surface treatment according to the specific needs of customers

🔹Technical consultation:

A professional team of engineers provides comprehensive design, selection and application technical support

🔹Product certification:

Provide complete material certification and test reports to ensure traceability and compliance with industry standards.

🔹Global logistics:

Provide customs clearance support with terms such as FOB, CIF and DDP.

Processing capabilities

We have advanced processing equipment and precision manufacturing technology to ensure that each Nickel 200 Fasteners reaches the world-class level:

High-precision CNC machining: Precision machining of threads and shapes to ensure that product dimensions and tolerances meet standards

Automated production line: Large-scale order production while ensuring product consistency and stability

Flexible, customized production: Flexible adjustment of process parameters according to customer needs to meet special requirements

Process optimization: Continuously improve production processes and process technologies to improve production efficiency and product quality

Quality control

Quality is our lifeline. TSM TECHNOLOGY CO., LTD implements a strict quality management system and monitors the production of Nickel 200 Fasteners throughout the process:

Raw material inspection: Strictly select high-quality raw materials to ensure that each batch meets international standards

Production process monitoring: Each process is strictly tested and recorded to ensure process stability

Finished product inspection: Including multiple tests such as size, mechanical properties and corrosion resistance to ensure excellent product performance

Third-party certification: Regularly accept independent agency testing to continuously meet ISO 9100 certification requirements

Contact us

For more details on Nickel 200 Fasteners or to obtain a quote, please contact TSM TECHNOLOGY CO., LTD at: info@tsmfasteners.com. We look forward to working with you to provide high-quality fastener solutions for your project.

Keywords: Nickel 200 fasteners,Nickel Alloy 200 Fasteners,Nickel 200 bolts,Nickel 200 screws,Nickel 200 Washers,Nickel 200 Studs,Nickel 200 Threaded,Nickel 200 Nuts

TSM factory and Processing equipment

Certificate