Brand: TSM

Material: Nickel, Nickel Alloy

Size :M2.5-M32 or Customized

Length: 1mm-1990 mm or customized

Application: Mechanical manufacturing, Construction engineering, Automobile industry, Electronics and electrical appliances

Standards: ASTM, DIN, JIS, BS, GB/T

EN10204 3.1/3.2, Third Party Inspection Report, etc

Delivery time: 10-25 days

Payment terms: T/T, L/C, Paypal, West Union or as required

TSM TECHNOLOGY CO., LTD is your trusted supplier of high-performance nickel alloy fasteners. We specialize in providing high-quality fasteners and components made of special corrosion-resistant alloys. These fasteners are designed to withstand the most demanding environments. Our products are designed for use in extreme conditions and have excellent resistance to heat, pressure and chemical corrosion.

What are nickel alloy fasteners?

Nickel alloy fasteners are high-performance components (bolts, nuts, washers, screws, etc.) made of nickel-based alloys (e.g. Inconel 718, Monel K500, Hastelloy C276) designed for:

- Extreme temperatures: -270°C to 1,200°C (cryo to supersonic environments).

- Corrosive media: Resistant to hydrogen sulfide, seawater, sulfuric acid, and chlorides.

- High stress: tensile strength up to 1,800 MPa (according to ASTM F3056).

Nickel alloy fasteners are widely used due to their strength and ductility. Nickel-based superalloys have high strength and high temperature resistance and are suitable for high stress, high heat applications. Nickel alloys are characterized by their corrosion resistance and the high strength and high temperature resistance characteristics of other nickel alloys. Monel®, Hastelloy®, and Inconel® are widely used nickel alloys. While they also produce high-strength fasteners, nickel alloy bolts, screws, nuts and studs are difficult to machine and require special treatment to avoid work hardening and embrittlement.

Technical Specifications

Material: Inconel 625/718, Monel 400, Nickel 201, Hastelloy C22

Size Range: M3–M42

Supply Type: Bolts, Nuts, Washers, Screws, etc.

Custom Manufacturing: From Prototype to Mass Production (MOQ 100 Pieces)

Common Nickel Alloy Grades for Fasteners

Alloy Name | UNS Number | Key Features | Typical Applications |

Monel 400 | N04400 | Saltwater corrosion resistant | Marine, chemical processing |

Inconel 600 | N06600 | Heat & oxidation resistant | Furnaces, nuclear reactors |

Inconel 718 | N07718 | High strength to 700°C | Aerospace, gas turbines |

Hastelloy C276 | N10276 | Acid resistant | Chemical plants, pollution control |

Nickel 200 | N02200 | Pure nickel, excellent conductivity | Food processing, caustic environments |

Key Benefits of Nickel Alloy Fasteners

✔10 times longer service life compared to stainless steel in offshore oil and gas.

✔EMI shielding capabilities for aerospace electronics.

✔ Superior corrosion resistance - it withstands acids, alkalis, and saltwater. No galvanic corrosion in multi-metal assemblies.

✔ High-temperature performance - maintains strength up to 1200°C (2192°F)

✔ Oxidation resistance - prevents scaling in extreme heat

✔ Excellent mechanical properties - high tensile and creep strength

Applications

TSM Nickel alloy fasteners are widely used in a variety of industries, including but not limited to:

🔹Aerospace: Used in aircraft structures, engine components and other critical connections

🔹Automotive: Used in chassis, engines and transmission systems to ensure long-term and efficient operation

🔹Electronic Equipment: Provides a stable fixing solution for precision instruments and high-tech equipment

🔹Industrial Machinery: Plays a vital role in connecting heavy-duty machinery and equipment

🔹Marine Engineering: Resists salt spray corrosion to ensure safe operation of ships and offshore platforms

TSM Advanced Machining Capabilities

State-of-the-art Manufacturing

CNC Machining: 5-axis machining center (±0.002 mm tolerance).

Cold forming: 1,200-ton press for high volume production.

Heat treatment: Vacuum annealing (AMS 2750 high temperature control).

Thread rolling: Anti-seizure threads by AS8879.

Quality control

Quality is our core value. TSM TECHNOLOGY CO., LTD implements strict quality control on every nickel alloy fasteners production link. The main measures include:

Raw material testing: Strictly screen suppliers to ensure that each batch of raw materials meets high standards

Full process monitoring: From production to packaging, real-time monitoring and recording of key data

Product testing: Implement multiple physical, chemical and mechanical property tests to ensure that the product meets or exceeds the standards

Certification testing: Regularly accept third-party testing to ensure the continuous and stable quality of Nickel alloy fasteners products

Contact us

For more details on Nickel alloy fasteners or to obtain a quote, please contact TSM TECHNOLOGY CO., LTD at: info@tsmfasteners.com. We look forward to working with you to provide high-quality fastener solutions for your project.

Keywords: Nickel alloy fasteners,nickel alloy screws,Nickel alloy screws and bolts,Nickel nuts,Nickel Washers,Nickel alloy bolts,Nickel Studs,Nickel fasteners

TSM factory and Processing equipment

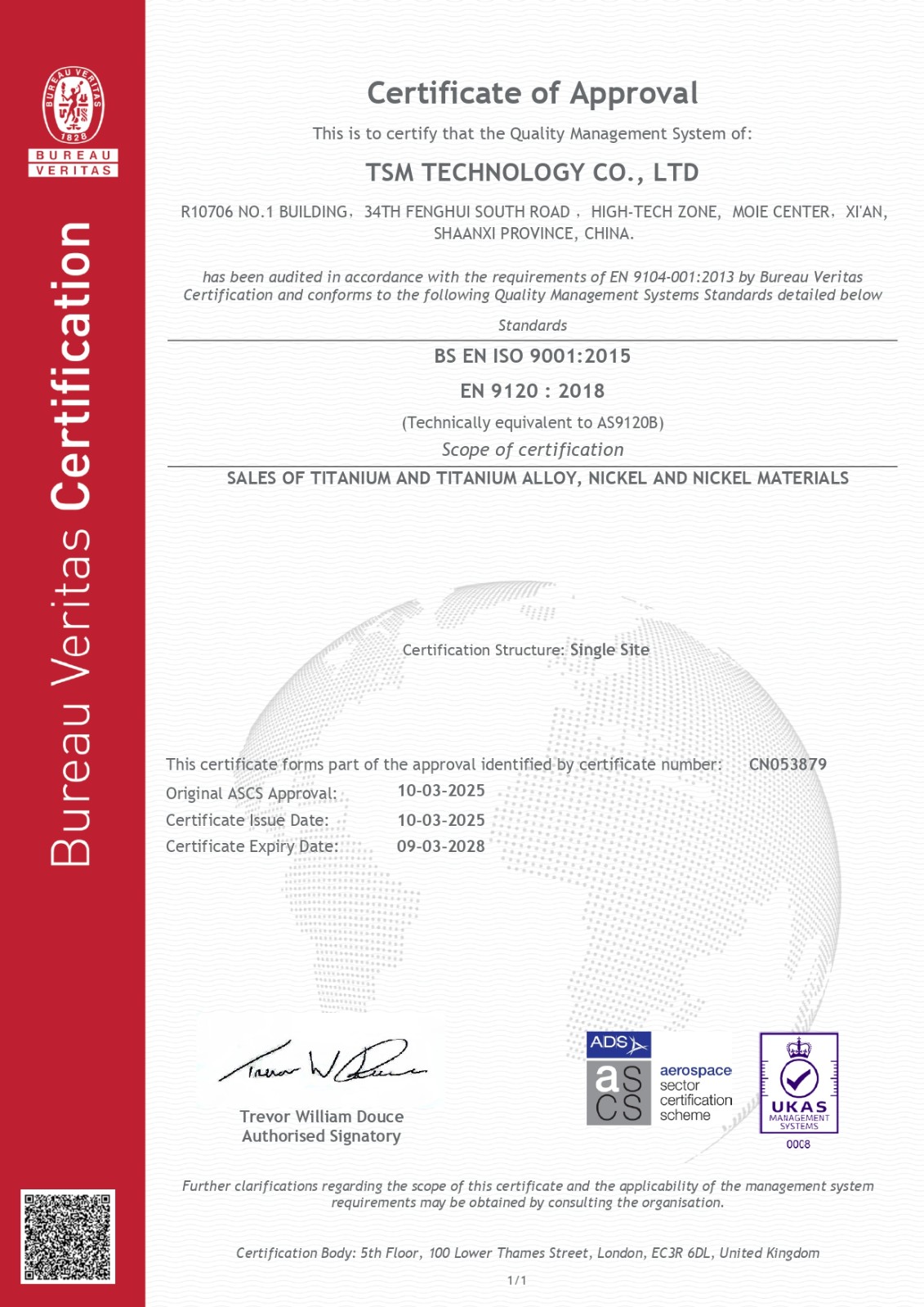

Certificate