Brand: TSM

Material: Nickel

Application: Mechanical manufacturing, Construction engineering, Automobile industry, Electronics and electrical appliances

Standards: ASTM, DIN, JIS, BS, GB/T

EN10204 3.1/3.2, Third Party Inspection Report, etc

Delivery time: 10-25 days

Payment terms: T/T, L/C, Paypal, West Union or as required

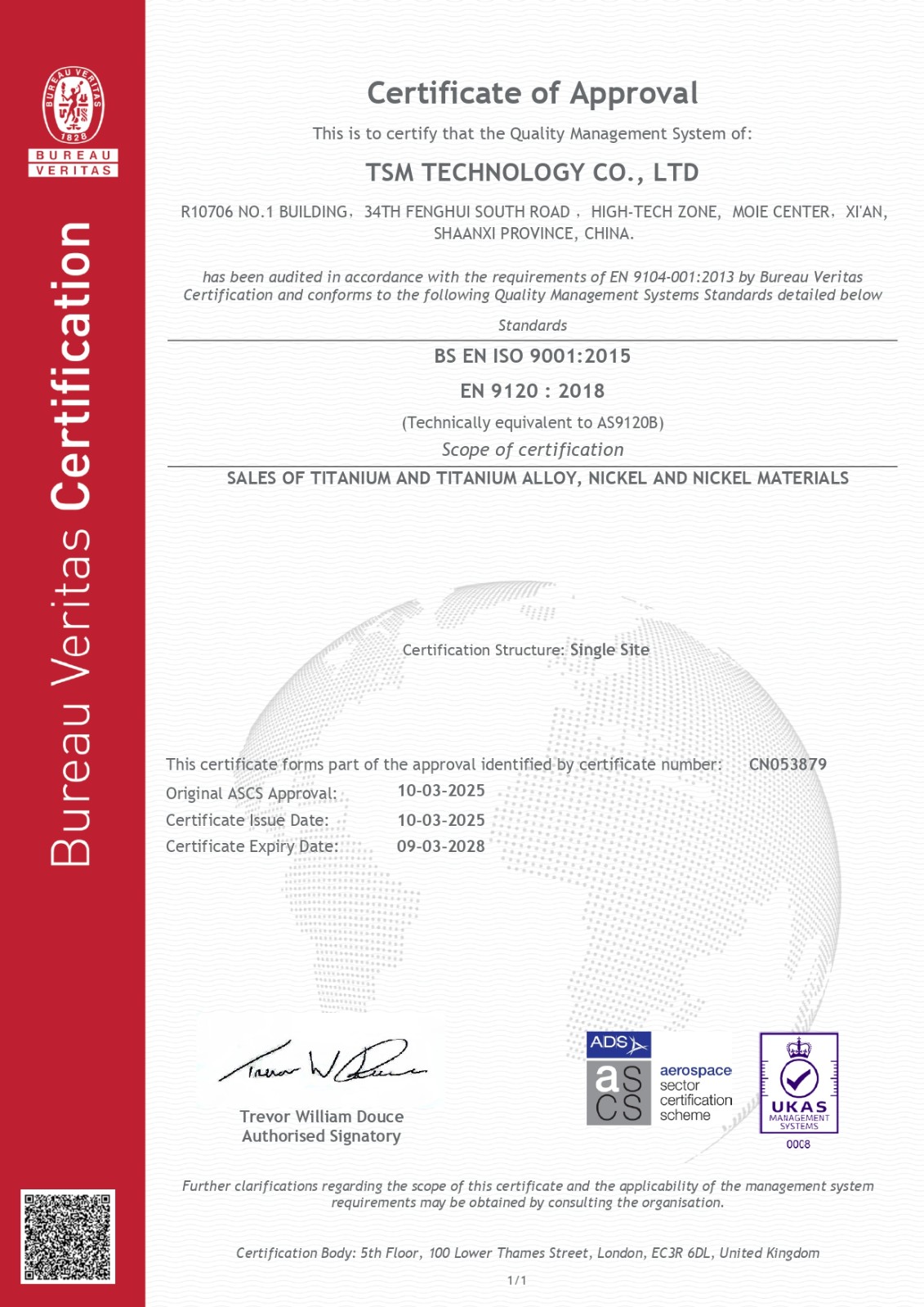

TSM TECHNOLOGY CO., LTD. is a well-known manufacturer and supplier with AS9120 aerospace certification. We are committed to the research, development, production and sales of high-end fasteners, providing high-quality products and solutions for aerospace, automotive, electronics, chemical and other high-demand industries. Relying on advanced production equipment and strict quality management system, we have accumulated rich experience in the field of Nickel Machine Screws and other products, and won the wide trust of customers around the world.

What is Nickel Machine Screws?

Nickel Machine Screws are machine screw products made of high-quality nickel alloy materials. Machine screws are small screws with a uniform diameter and threading, used to fasten metal parts. Machine screws are often used with nuts or threaded holes in machinery and electronics for precise fastening. After special nickel surface treatment, these screws have excellent corrosion resistance, oxidation resistance and high mechanical strength, and can maintain long-term stable connection effects in various harsh environments. Whether in high temperature, humidity or chemical corrosion, Nickel Machine Screws can provide excellent fastening solutions.

Specifications

Our Nickel Machine Screws products cover a variety of specifications to meet the application needs of different industries. The main specifications include:

1.Size Range: Available in a variety of diameters (such as M1.5 to M24 and above) and lengths (regular sizes can be customized)

2.Thread Standard: Thread design that meets international standards (such as ISO, DIN, ANSI, etc.)

3.Surface Treatment: Options include natural, polished or coated surface treatment to improve performance in specific environments.

Tolerance and precision: strictly control product tolerances to ensure efficient and stable fastening effects in precision assembly

4.Material: Nickel or nickel alloys, such as Nickel 200, Inconel and Monel.

Alloy Type and Material Grade

Inconel® | 600/601/625/718 |

Hastelloy® | C276/C22/B3 |

Monel® | 400/K500 |

Incoloy® | 800/825 |

Nickel | 200/201 |

Nickel Machine Screws Types

According to different application scenarios, we provide a variety of Nickel Machine Screws, mainly including:

🔹Standard flat head screws: suitable for mechanical assembly, electronic equipment and other occasions requiring a flat surface

🔹Countersunk screws: used to be embedded in the fixings to ensure smooth and beautiful installation

🔹Cross slot/slot screws: convenient for quick installation and removal using various electric or manual tools

🔹Self-tapping screws: suitable for fastening metal or plastic parts without pre-drilling

🔹Customized screws: designed according to customer's special needs to meet non-standard size and special function requirements

Machine screws have several key advantages over regular screws

1. They are manufactured with tighter tolerances, have finer threads, and are more consistent overall.

2. Unlike regular screws that have a partially threaded shank, machine screws are threaded almost the entire length, providing a larger gripping area for a more secure grip.

3. Machine screws also have flat or blunt heads designed to fit snugly in pre-drilled and threaded holes.

These features make them ideal for applications that require security and precision fastening.

Application fields

Nickel Machine Screws are widely used in many fields due to their excellent corrosion resistance, stability and high mechanical strength, including but not limited to:

✔Aerospace: fasteners for key structural components to ensure high safety and durability

✔Automobile manufacturing: precision connections in engines, chassis, transmission systems, etc.

✔Electronic and electrical equipment: high-precision equipment and circuit board assembly to ensure stability and reliability

✔Chemical and petrochemical: maintain stable connections in corrosive environments to ensure long-term safe operation of equipment

✔Industrial machinery: precision fasteners used in various mechanical equipment, instruments and meters

Services we provide

To meet the diverse needs of customers, TSM TECHNOLOGYCO., LTD. provides comprehensive one-stop services, mainly including:

Heat treatment: state-of-the-art heat treatment facilities to optimize material properties.

Customized product design: provide personalized size, head shape and surface treatment solutions according to your requirements

Certification support: Factory test report (MTR), material compliance, 3.1/3.2 material certificate.

Prototype and mass production: CNC machining (prototype) and cold forging (up to 1 million pieces per month).

Processing capabilities

We have internationally leading processing equipment and advanced production processes to ensure that every Nickel Machine Screws meets high standards. Our processing capabilities are reflected in:

High-precision CNC machining: achieve precise machining of complex threads and shapes to meet high-precision assembly requirements

Automated production line: efficient production ensures consistency and stability of large-volume orders

Flexible customized production: quickly adjust process parameters according to customer needs to produce customized products

Continuous process optimization: continuously improve production processes to improve production efficiency and product quality

Contact us

For more details on Nickel Machine Screws or to obtain a quote, please contact TSM TECHNOLOGY CO., LTD at: info@tsmfasteners.com. We look forward to working with you to provide high-quality fastener solutions for your project.

TSM factory and Processing equipment

Certificate