Brand: TSM

Material: Nickel

Size :M2.5-M32 or Customized

Length: 1mm-1990 mm or customized

Application: Mechanical manufacturing, Construction engineering, Automobile industry, Electronics and electrical appliances

Standards: ASME,ANSI

ASME B18.2.2 – 2010

Delivery time: 10-25 days

Payment terms: T/T, L/C, Paypal, West Union or as required

Nuts are essential components in countless applications. They provide secure fastening solutions for machinery, buildings, and other critical systems. Finished nuts are fasteners with internal threads. They are used to secure parts together with bolts or screws. TSM specializes in providing high-quality nuts that meet stringent industry standards. We stock a wide range of nuts in a variety of materials, including specialty alloys such as Inconel, Hastelloy, and Monel. These nickel nuts are designed to withstand extreme environments. Whether you need standard sizes or custom specifications, our nuts provide reliable performance in a wide range of industries such as oil and gas, chemical processing, and aerospace.

Contact TSM today to start a quote.

Specifications

Nickel nuts specifications include:

Size range: M3 to M36

Thread types: Coarse and fine pitch

Material grade: Copper-nickel alloy (UNS C71500) conforming to ASTM F467

Standards: EN10204 3.1/3.2, Third Party Inspection Report

Alloy Type and Material Grade

Inconel® | 600/601/625/718 |

Hastelloy® | C276/C22/B3 |

Monel® | 400/K500 |

Incoloy® | 800/825 |

Nickel | 200/201 |

Nickel nut types

✔Hexagonal nuts: General-purpose nuts for standard fastening needs.

✔Lock nuts: Prevent loosening due to vibration and torque.

✔Winged nuts: Facilitate hand tightening and loosening.

✔Cap nuts: Protect bolt ends and provide an aesthetically pleasing appearance.

✔Flanged nuts: Built-in flanges distribute pressure evenly.

Application Fields

Nickel Nuts are widely used in many industries due to their excellent corrosion resistance and high strength properties:

✔Aerospace: Suitable for aircraft structures, engine components and other high-demand connection parts

✔Automobile manufacturing: Used in key parts such as automobile chassis, engine and suspension systems

✔Electronic equipment: Provides stable connection in high-precision instruments and electronic equipment

✔Industrial machinery: Widely used in various industrial machinery, equipment and assembly lines

✔Marine engineering: With excellent salt spray and corrosion resistance, suitable for ships and offshore platforms

Why work with TSM?

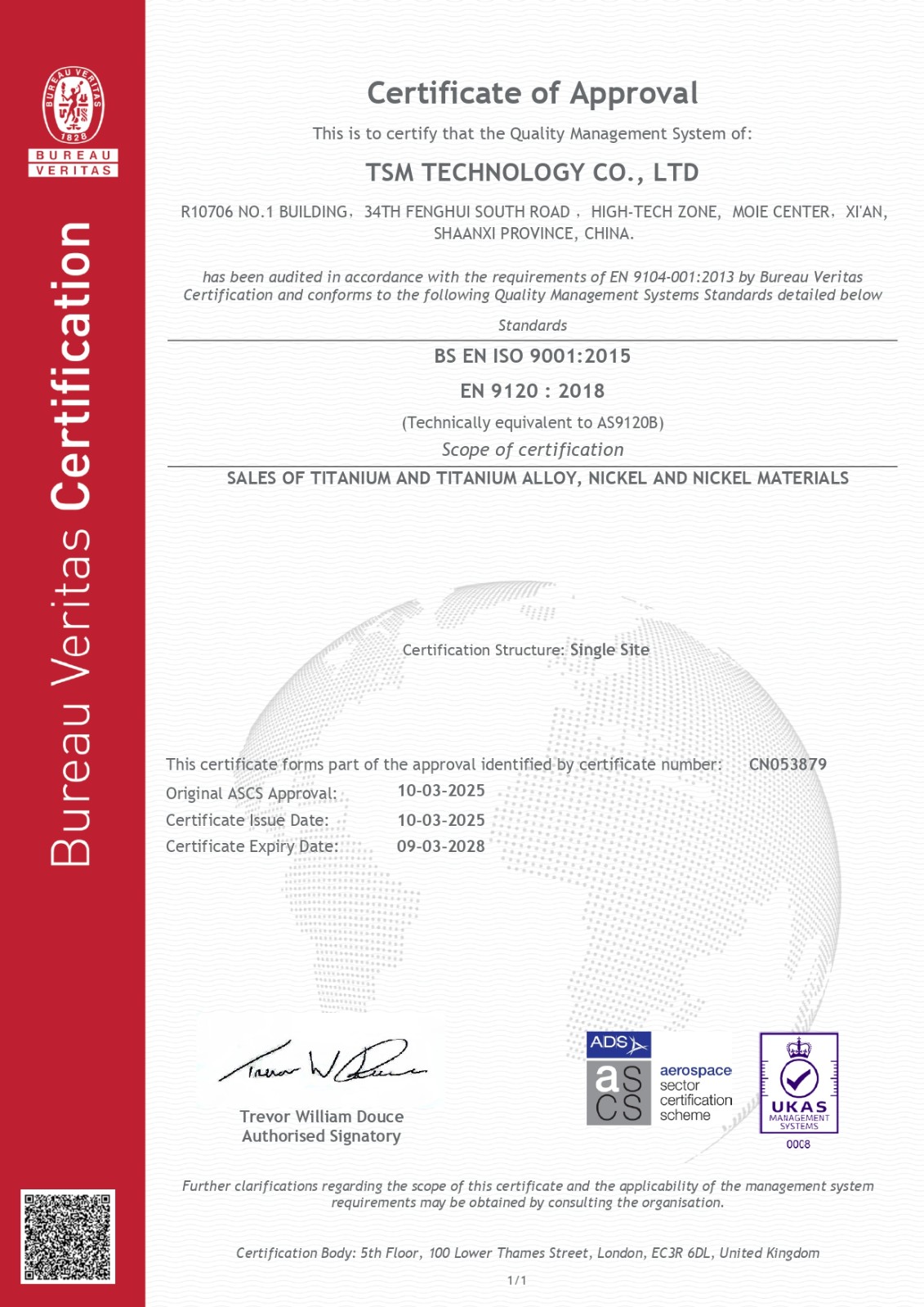

✅ Certified Excellence: AS9120 aerospace certified manufacturer.

✅ End-to-end control: Vertical integration from raw material procurement (conflict-free nickel) to precision processing.

✅ Global Influence: Provide technical support to more than 50 countries.

About TSM TECHNOLOGYCO., LTD

TSM TECHNOLOGY CO., LTD. is a leading manufacturer and supplier of AS9120 aerospace-certified products. We are committed to providing high-quality, high-performance industrial fastener solutions to customers around the world, especially in the fields of aviation, aerospace, automotive and high-precision equipment. With strict quality control and continuous innovative R&D capabilities, we have become a trusted partner of many well-known companies.

Services we provide

As a professional fastener manufacturer, TSM TECHNOLOGY CO., LTD. provides customers with one-stop services, including:

Product customization: Provide personalized size and design according to customer needs

Precision machining: CNC turning/threading, with a tolerance of ±0.005 mm.

Material testing: Third-party laboratory report, including tensile strength and pitting resistance

Technical Support: A professional team of engineers provides technical consultation and application solution suggestions

Fast delivery: Efficient production process and logistics management to ensure on-time delivery of products

Contact us

For more details on Nickel nuts or to obtain a quote, please contact TSM TECHNOLOGY CO., LTD at: info@tsmfasteners.com. We look forward to working with you to provide high-quality fastener solutions for your project.

TSM factory and Processing equipment

Certificate